We have access to a cavitation rheometer within our lab. This is a bespoke instrument, first demonstrated by the Crosby group.1,2 This instrument allows for the measurement of the localised mechanical properties of soft materials.

This is achieved by the growth of a cavitation bubble within the material and measuring the pressure at which this occurs (deemed the Critical Pressure, PC). This can then be compared across a sample or between samples to assess differences in localised mechanical properties. We have previously shown that this data can be correlated with elastic moduli measured through bulk oscillatory rheology.3 This technique can be carried out on much smaller samples than with oscillatory rheology. The instrument is also a lot more accessible to most when compared to an oscillatory rheometer. Our instrument consists of 3 parts: a syringe pump (1), connected to a needle; a modified 3D printer (2), to allow for precise position of the needle; the cavitation rheology analyser box (CRAB) (3), that contains a pressure gauge and acts as the brain of the instrument.

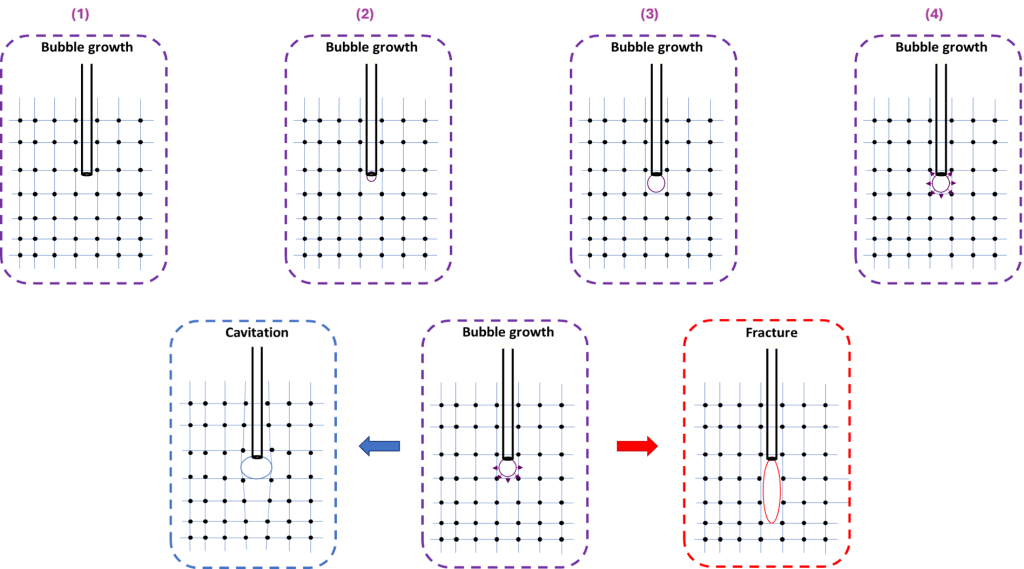

Cavitation is achieved by pumping a fluid (typically air, but water can also be used)4 through a needle into a soft material. Initially this will cause an increase in the pressure of the system (1). Eventually a small bubble will form at the tip of the needle (2). This exerts outwards pressure onto the surrounding material (3). As the material surrounding the bubble yields when then pressure is high enough, the bubble will rapidly and suddenly grow (or cavitate) (4). This is the critical pressure, PC.

During cavitation, the material can fail through either elastic (leading to true cavitation), or inelastic deformations (leading to fracture).5

References

1 – Soft Matter, 2007,3, 763-767

2 – Proc. Nat. Acad. Sci., 2020, 117, 9157-9165

3 – Soft Matter, 2019,15, 6340-6347

4 – J. Polym. Sci. B Polym. Phys., 48 (13), 1423-1427

5 – Soft Matter, 2009,5, 3963-3968